Automation

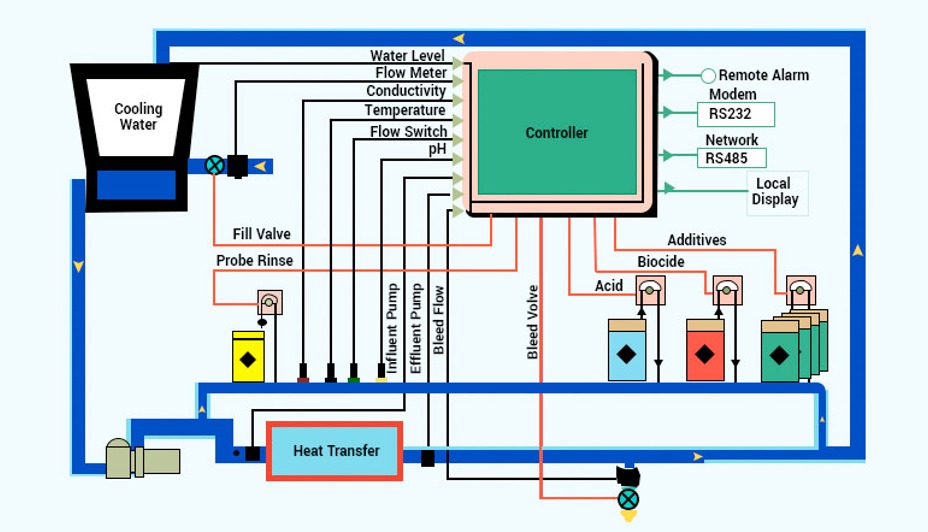

1. V-sense : Cooling tower / Boiler / Swimming Pool Automation

At Nirmaan WaterTech Solutions, we believe that our workforce is the most valuable resource. What sets us apart from other water treatment suppliers is our commitment to providing responsive, customized, and need-specific control systems.

Benefits of V-Sense Automation:

• Enhanced accuracy in parameter control

• Improved treatment administration and chemical dosing

• Reduced risk of human errors

• Capability for remote operations

• Minute-by-minute system data logging, essential for troubleshooting.

• Optimized energy, water, and chemical usage, ensuring maximum value for every rupee spent.

Advantage of the V-Sense Dosing System for the Cooling Tower System:

At the core of our V-Sense system are principles of optimal performance, sustainability, and efficiency. With its advanced features, V-Sense not only enhances water treatment processes but also provides numerous additional benefits.

- Water Saving: Intelligently regulates solenoid valves to open only when TDS surpasses a setpoint, ensuring efficient water usage without compromising quality.

- Chemical Saving: Customizes chemical dosing based on real-time data, optimizing consumption, and reducing waste.

- Optimized Disinfection: Enhances disinfection by minimizing adverse impacts of biocide combinations, ensuring safer and more effective processes during bleed lockout.

- Energy Saving: Reduces energy usage by preventing efficiency losses from scale and microbiological accumulation.

- Asset Protection: Continuously monitors and adjusts critical parameters like pH and ORP, protecting equipment such as heat exchangers and condensers.

- Green Technology: Demonstrates commitment to sustainability by minimizing water and chemical usage and their discharge.

- Direct Chemical Dosing: Provides real-time feedback to dosing pumps, eliminating the need for manual chemical preparation and handling, improving efficiency and safety.

2. Timer Based Dosing

A timer-based dosing system injects precise quantities of chemicals at predetermined intervals, commonly used in industrial processes and water treatment.

Advantages:

- Precise Control: Ensures exact chemical addition, improving process efficiency and effectiveness.

- Cost Reduction: Minimizes chemical waste, lowering overall process costs.

- Ease of Use:Easily set up and configured with PLC and SCADA systems, requiring minimal manual intervention.

- Reliability: Delivers accurate chemical dosages consistently, ensuring optimal process performance.

3. Acid / Hypo Dosing System

An acid/hypo dosing system precisely introduces a specific amount of acid into a process, typically to adjust pH levels or remove impurities.

Key Components:

- Storage Tank: Made of plastic or stainless steel to withstand acid corrosion.

- Metering Pump: Dispenses precise amounts of acid, controllable manually or automatically.

- Control System: Monitors and regulates dosing with pH sensors and control valves.

- Valves and Piping: Direct acid flow, made from corrosion-resistant materials.