Chlorine Dioxide Treatment

Chlorine dioxide is one of the fastest growing Chlorine alternatives in water treatment application. This technology offers the benefit of effectiveness at high pH, being unaffected by ammonia, and demonstrating significant advantages over Chlorine in systems susceptible to high levels of organic contaminants also for systems wherein minimum oxidant levels in water is serious concern in view of effluent discharge. Because chlorine dioxide is a selective oxidizer, its ability to control microorganisms in water at very low dosages makes it an especially cost-effective solution.

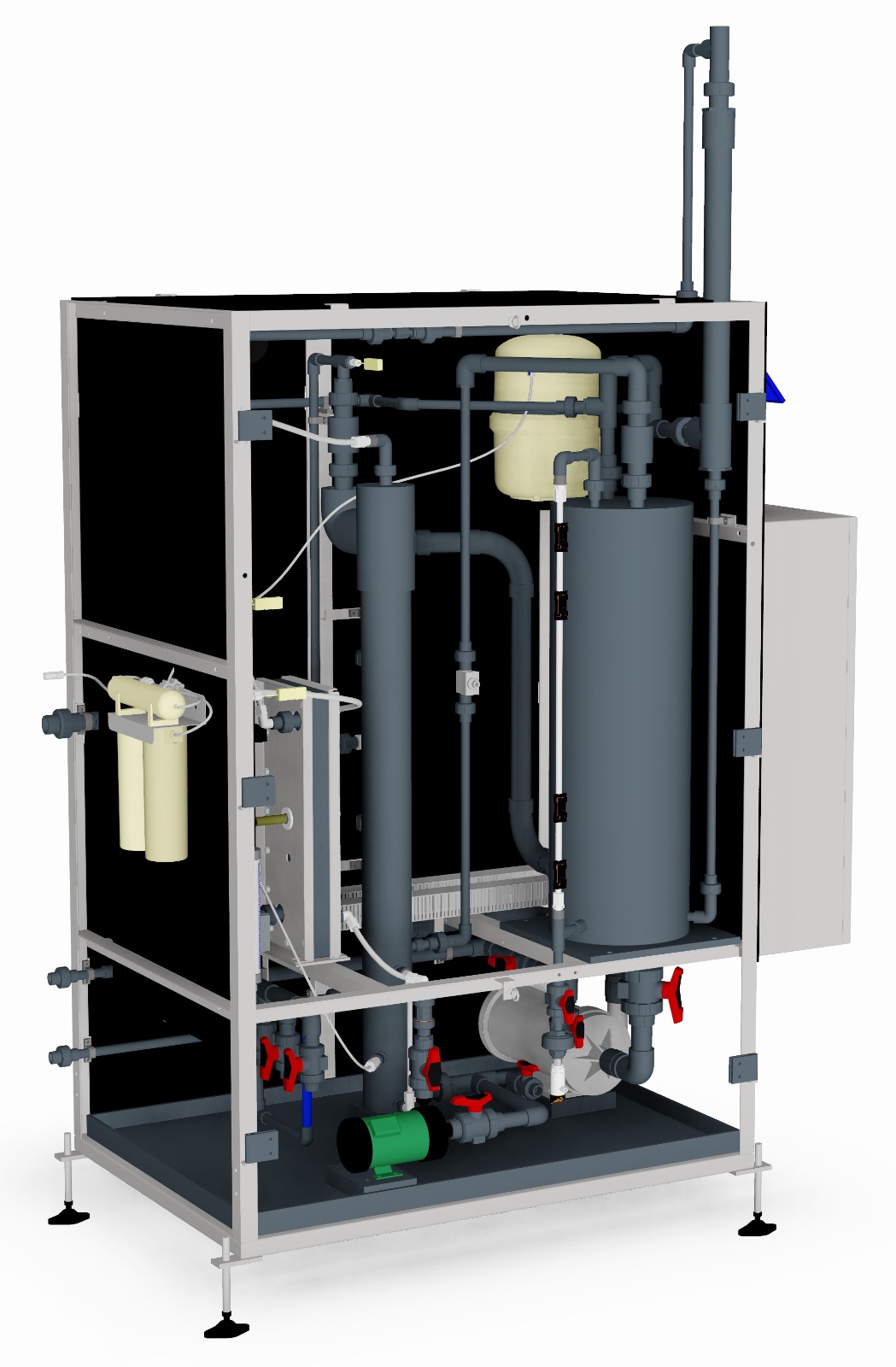

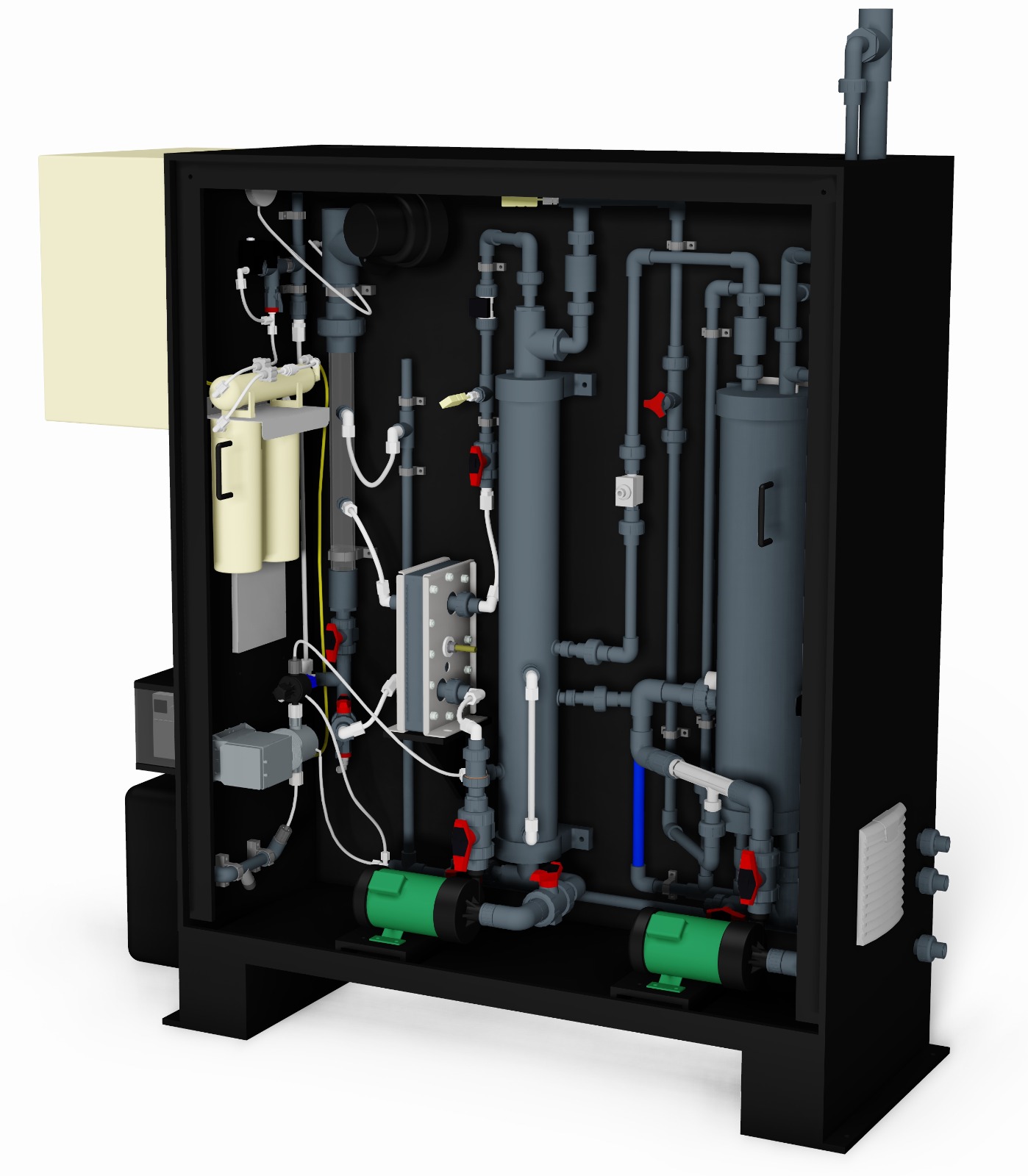

1. Chlorine Dioxide Generator :

A chlorine dioxide generator is a device that produces chlorine dioxide, an exceptionally effective oxidizing and bleaching agent, by combining chlorine and an oxygen source such as sodium chlorite.

One key advantage of using chlorine dioxide as a disinfectant is its effectiveness in eliminating a wide range of microorganisms, including bacteria, viruses, and spores. It also excels at removing color and odor from water, making it a popular choice for water treatment and sewage treatment plants.

Chlorine dioxide is also beneficial because it produces fewer harmful byproducts when reacting with organic matter in water, unlike traditional chlorine disinfection, which can create harmful byproducts like trihalomethanes and haloacetic acids.

Moreover, chlorine dioxide is effective at lower concentrations and across a broader pH range compared to chlorine, enhancing its versatility as a disinfectant.

Additionally, chlorine dioxide has various industrial uses, such as bleaching paper, textiles, and wood pulp, and acting as a sanitizer in food and beverage processing plants.

In summary, a chlorine dioxide generator produces chlorine dioxide, a powerful agent for oxidizing and bleaching. It is highly effective at killing a wide range of microorganisms, works efficiently at lower concentrations and across a wider pH range, and produces fewer harmful byproducts, making it a versatile disinfectant.

2. O & M of CIO2 System :

Operation and Maintenance (O&M) of a Chlorine Dioxide (ClO2) system is essential to ensure the system works correctly and produces safe, effective levels of ClO2.

Monitoring: Regularly check the ClO2 system to ensure it is producing the right amount of ClO2 and functioning properly. This includes monitoring water pH levels, temperature, chlorine dioxide residuals, and water flow rate.

Maintenance: Perform routine maintenance on the ClO2 system to keep it in good working order. This involves cleaning and servicing equipment such as the chlorine dioxide generator, dosing pumps, and storage tanks.

Safety: Safety is crucial when handling ClO2. The system should be designed to minimize the risk of chlorine dioxide gas release, and proper personal protective equipment (PPE) should be used.

Record Keeping: Accurate record-keeping is vital for effective O&M. Maintain detailed records of monitoring data, maintenance activities, safety procedures, and any incidents.

Compliance: Ensure the ClO2 system complies with all local, state, and federal regulations. Obtain necessary permits and meet any reporting requirements.